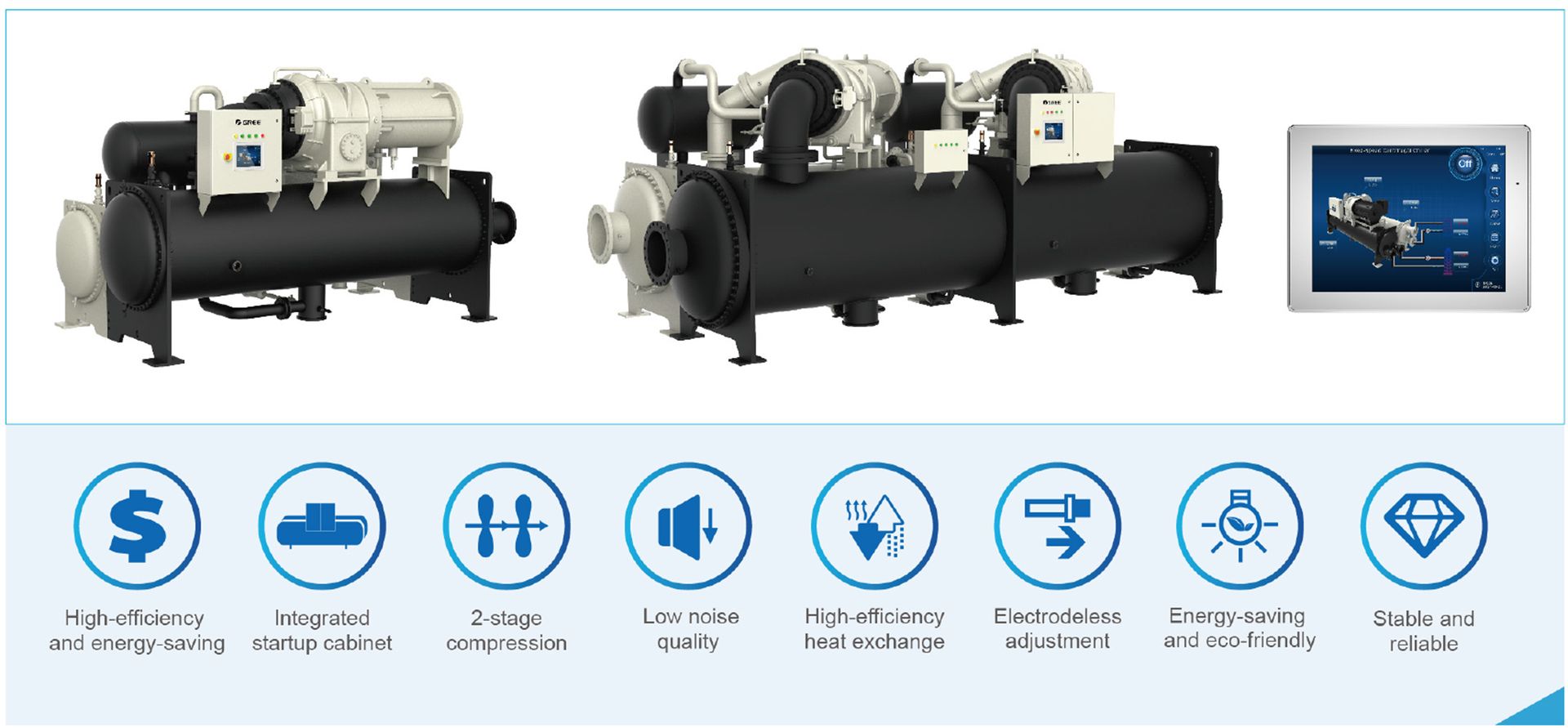

• Features

A new generation of fixed-speed centrifugal chiller, with two-stage compression technology, is highly efficient, energy-saving, safe and reliable.

- Two-stage compression enthalpy-adding technology and economizer are adopted to improve efficiency by 5-6% compared with one-stage cooling circulation system. Rotation speed of compressor is reduced, operation reliability is improved and lifespan is prolonged. Meanwhile, surge margin is wide and operation range is wide.

- Variable-area diffuser is adopted to effectively improve surge margin and system operation range, and reduce noise and vibration.

- With integrated startup cabinet and wire connection in the factory, user only needs to provide power cord, so wire connection during installation is simplified and floor area of startup cabinet is reduced.

- Semi-enclosed motor and helical refrigerant ejecting cooling technology is adopted to not only reduce the risk of refrigerant and lubricant leakage, but also prevent heat dissipation in machine room, reducing the cooling device cost and operation cost.

- New heat exchanger specially designed for centrifugal chiller contributes to even distribution of refrigerant, rational temperature field and heat exchange rate improvement; meanwhile, the heat exchanger adopts high-efficiency heat exchange tube for reducing heat transfer resistance and improving the system’s cooling capacity and energy efficiency ratio.

- User-friendly touch screen is adopted for convenient operation.

- High-performance digital signal processing and intelligent control technology is adopted.

- Vaned diffuser with the optimized ratio between the vane width and spacing.